Page 11 - Guide to Managing Trade Effluent - 2023

P. 11

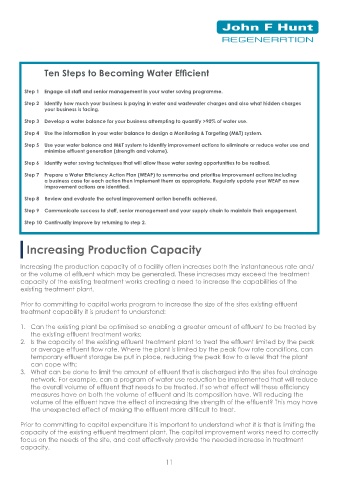

Options for Cost Reduction Ten Steps to Becoming Water Efficient

Modifications/upgrades to a site’s existing effluent treatment plant increases the opportunity to

reduce costs though a number of routes, such as: Step 1 Engage all staff and senior management in your water saving programme.

Step 2 Identify how much your business is paying in water and wastewater charges and also what hidden charges

• Decreased operator intervention via increased levels of automation. your business is facing.

• Reduced effluent treatment costs.

• Reduced waste disposal costs. Step 3 Develop a water balance for your business attempting to quantify >90% of water use.

• Reduced water consumption through increased rates of water recycling. Step 4 Use the information in your water balance to design a Monitoring & Targeting (M&T) system.

• Reduced trade effluent charges.

• Reduced waste disposal costs. Step 5 Use your water balance and M&T system to identify improvement actions to eliminate or reduce water use and

• Reduced maintenance costs. minimise effluent generation (strength and volume).

Step 6 Identify water saving techniques that will allow these water saving opportunities to be realised.

There is a potential that the financial savings made will pay back the capital investment within a

short period of time; increasing the overall profitability of the business. Step 7 Prepare a Water Efficiency Action Plan (WEAP) to summarise and prioritise improvement actions including

a business case for each action then implement them as appropriate. Regularly update your WEAP as new

improvement actions are identified.

Planning for Changes to the Operating Process Step 8 Review and evaluate the actual improvement action benefits achieved.

Step 9 Communicate success to staff, senior management and your supply chain to maintain their engagement.

Where there is a planned change in the nature of the process to be undertaken at a facility

the impacts which the change may have on the ability of the sites effluent treatment plant Step 10 Continually improve by returning to step 2.

to cope with the change, ensuring that the site remains compliant needs to be assessed with

modifications/upgrades built into the program for completing the planned operational changes.

Key points which need to be addressed early on in the planning process are: Increasing Production Capacity

• What effect will the planned change have on both the peak flow rate needed to be handled

by the effluent treatment plant and the total volume of effluent that will need to be altered. Increasing the production capacity of a facility often increases both the instantaneous rate and/

• Will the composition of the effluent change, that is will new pollutants be introduced that need or the volume of effluent which may be generated. These increases may exceed the treatment

to be treated and/or will the strength (concentration) of the effluent become changed. capacity of the existing treatment works creating a need to increase the capabilities of the

existing treatment plant.

• Does the existing trade effluent consent need to be amended and will the sewage undertaker

use this opportunity to impose, new or amended stricter conditions on the quality of the effluent

that can be discharged. Prior to committing to capital works program to increase the size of the sites existing effluent

• Will the existing plant be able to operate and ensure that the treated effluent discharged into treatment capability it is prudent to understand:

the sewer remains compliant with the discharge conditions.

1. Can the existing plant be optimised so enabling a greater amount of effluent to be treated by

the existing effluent treatment works;

The development of a new production capability and the assessment of the requirements to treat

the effluent need to be made concurrently. 2. Is the capacity of the existing effluent treatment plant to treat the effluent limited by the peak

or average effluent flow rate. Where the plant is limited by the peak flow rate conditions, can

temporary effluent storage be put in place, reducing the peak flow to a level that the plant

can cope with;

3. What can be done to limit the amount of effluent that is discharged into the sites foul drainage

network. For example, can a program of water use reduction be implemented that will reduce

the overall volume of effluent that needs to be treated. If so what effect will these efficiency

measures have on both the volume of effluent and its composition have. Will reducing the

volume of the effluent have the effect of increasing the strength of the effluent? This may have

the unexpected effect of making the effluent more difficult to treat.

Prior to committing to capital expenditure it is important to understand what it is that is limiting the

capacity of the existing effluent treatment plant. The capital improvement works need to correctly

focus on the needs of the site, and cost effectively provide the needed increase in treatment

capacity.

10 11