Page 13 - Guide to Managing Trade Effluent - 2023

P. 13

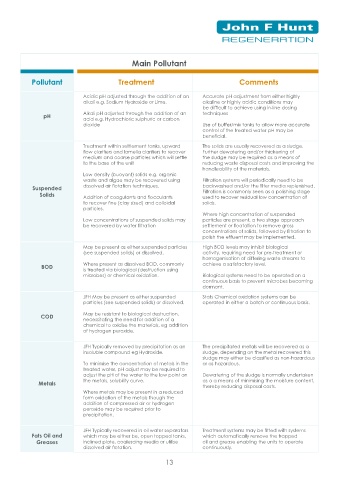

Treatment Solutions Main Pollutant

Effluent Treatment is commonly categorised according to the following stages: Pollutant Treatment Comments

Preliminary Treatment: Initial recovery of large solids by screening. Various types of static and Acidic pH adjusted through the addition of an Accurate pH adjustment from either highly

alkali e.g. Sodium Hydroxide or Lime.

alkaline or highly acidic conditions may

mechanical screens may be used. Preliminary treatment can also include the operation of be difficult to achieve using in-line dosing

“balancing tanks” used to even out the flow and strength of the effluent prior to subsequent pH Alkali pH adjusted through the addition of an techniques

treatment. acid e.g. Hydrochloric sulphuric or carbon Use of buffer/mix tanks to allow more accurate

dioxide

control of the treated water pH may be

Primary Treatment: This stage is characterised by the removal of gross levels of suspended beneficial.

particles and/or the oil and grease. Commonly involve the use of pH adjustment unit, oil water Treatment within settlement tanks, upward The solids are usually recovered as a sludge.

separators, settlement units (clarifiers), or dissolved floatation units (DAF). flow clarifiers and lamella clarifiers to recover Further dewatering and/or thickening of

medium and coarse particles which will settle the sludge may be required as a means of

to the base of the unit reducing waste disposal costs and improving the

Secondary Treatment: Frequently biological treatment using microbes to remove organic handleability of the materials.

materials which have not been removed by the previous treatment stages. Treatment is either Low density (buoyant) solids e.g. organic

down the effluent. The use of anaerobic reactors is usually a first stage treatment to break down waste and algae may be recovered using Filtration systems will periodically need to be

dissolved air flotation techniques.

backwashed and/or the filter media replenished.

particularly high strength effluent before treatments in a second aerobic stage. Both processes Suspended Filtration is commonly seen as a polishing stage

are relatively slow and may necessitate the use of large tanks/lagoons or compact mechanical Solids Addition of coagulants and flocculants used to recover residual low concentration of

systems. Biological treatment is a sensitive process requiring controlled operating conditions with to recover fine (clay sized) and colloidal solids.

particles.

constant effluent supply. Where high concentration of suspended

Low concentrations of suspended solids may particles are present, a two stage approach

Tertiary Treatment: Considered to be a final cleaning/polishing stage, used if necessary to remove be recovered by water filtration settlement or floatation to remove gross

any remaining traces of contamination or to produce a high quality treated effluent that may concentrations of solids, followed by filtration to

polish the effluent may be implemented.

enable the water to be re-used (recycled) for specific low risk uses. Treatment process can include

fine filtration (sand filtration, nano-filtration), reverse osmosis, nitrification, granular activated May be present as either suspended particles High BOD levels may inhibit biological

(see suspended solids) or dissolved.

activity, requiring need for pre-treatment or

carbon or sterilisation/disinfection. homogenisation of differing waste streams to

BOD Where present as dissolved BOD, commonly achieve a satisfactory level.

is treated via biological (destruction using

microbes) or chemical oxidation. Biological systems need to be operated on a

continuous basis to prevent microbes becoming

dormant.

JFH May be present as either suspended Stats Chemical oxidation systems can be

particles (see suspended solids) or dissolved. operated in either a batch or continuous basis.

COD May be resistant to biological destruction,

necessitating the need for addition of a

chemical to oxidise the materials, eg addition

of hydrogen peroxide.

JFH Typically removed by precipitation as an The precipitated metals will be recovered as a

insoluble compound eg Hydroxide. sludge, depending on the metal recovered this

sludge may either be classified as non-hazardous

To minimise the concentration of metals in the or as hazardous.

treated water, pH adjust may be required to

adjust the pH of the water to the low point on Dewatering of the sludge is normally undertaken

Metals the metals, solubility curve. as a a means of minimising the moisture content,

thereby reducing disposal costs.

Where metals may be present in a reduced

form oxidation of the metals though the

addition of compressed air or hydrogen

peroxide may be required prior to

precipitation.

JFH Typically recovered in oil water separators Treatment systems may be fitted with systems

Fats Oil and which may be either be, open topped tanks, which automatically remove the trapped

Greases inclined plate, coalescing media or utilise oil and grease enabling the units to operate

dissolved air flotation. continuously.

12 13